Roller Chains

We are Authorized Distributor, Dealer, Supplier of Diamond Roller Chains like Industrial Chains, Standard Roller Chains, Power Transmission Chains, Diamond Industrial Roller Chains, Power Transmission Roller Chains, Single Strand Roller Chains, Diamond Simplex Strand Roller Chains, Diamond American Standard Roller Chains, Diamond European Series Roller Chains, Diamond Duplex Strand Roller Chains, Diamond Triplex Strand Roller Chains, Single Strand Roller Chains, Double Strand Roller Chains, Triple Strand Roller Chains, Simplex Roller Chains, Duplex Roller Chains, Triplex Roller Chains, Diamond Simplex Roller Chains, Diamond Duplex Roller Chains, Diamond Triplex Roller Chains, Straight Side Plate Chains, Double Pitch Chains, Double Pitch Roller Chains, Double Pitch Drive Chains, Double Pitch Conveyor Chains and our setup is situated in Mumbai, Maharashtra, India.

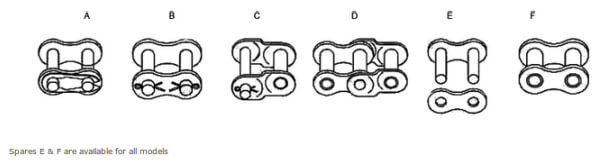

Roller chains are constructed like a typical chain link structure that is a series of cylindrical rollers connected by links. A rotating sprocket which is connected to the motor moves the chain. The other end of the chain can then be connected to some part of the load.

Standard Series :

European Series - BS/ DIN/ ISO

The European series of roller chains are designed for use in mechanical power transmission systems

» Single Strand

» Double Strand

» Triple Strand

Simplex : Single Strand

Duplex: Double Strand

Triplex: Triple Strand